What is it a Laser Plastic Cutting Machine?

Yo, what’s up, squad! Welcome to the dope universe of precision crafting, where we’re about to dive headfirst into the awesomeness of plastic laser cutting machines. 🚀

Alright, so check it – ever wondered how those rad designs on your favorite gadgets or DIY projects come to life? Say hello to plastic laser cutting machines, the unsung heroes of modern manufacturing and DIY scenes! These bad boys ain’t just tools – they’re game-changers, helping peeps like us turn our wildest ideas into reality

Stick around, ’cause we’re about to uncover the secrets behind these epic machines and explore how they’re shaking up the crafting game. Get ready to unleash your creativity like never before – it’s gonna be lit! 🔥🔥🔥

Understanding Plastic Laser Cutting Machines.

Alright, listen up, fam! Time to break down the nitty-gritty of plastic laser cutting machines in a way even your grandma could understand. 🤓

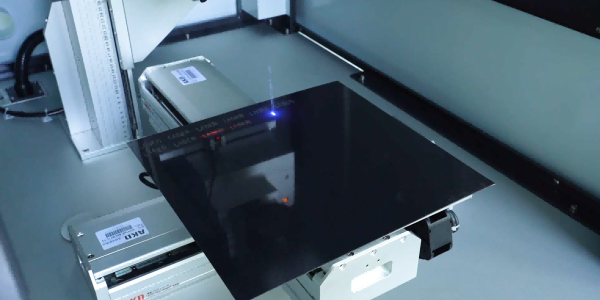

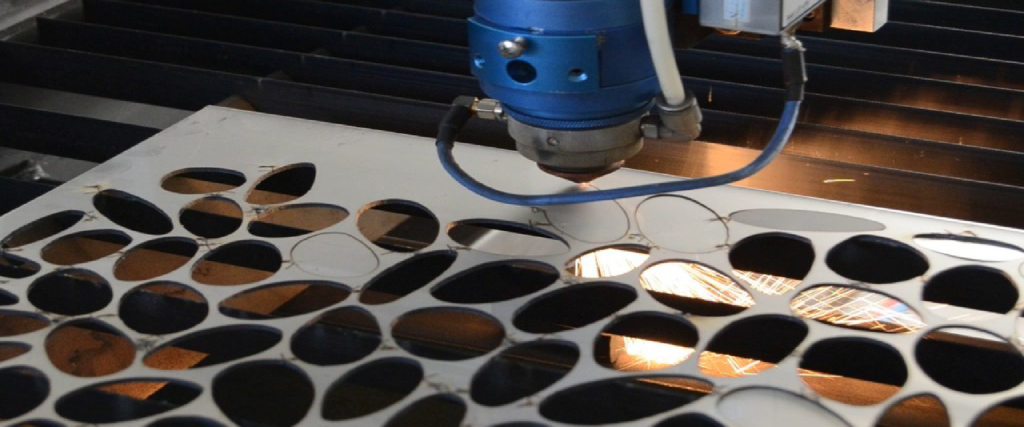

First off, let’s talk laser cutting tech – it’s like something straight outta a sci-fi flick, except it’s real and totally mind-blowing! Picture this: lasers, yeah, those crazy beams of light, zapping through plastic like it’s no biggie. Basically, these machines use super-focused lasers to slice and dice through plastic with surgical precision. It’s like wielding a lightsaber, but instead of battling Sith Lords, you’re crafting epic DIY projects. How sick is that?

So yeah, whether you’re whipping up custom phone cases, pimping out your ride with acrylic accents, or just flexing your DIY skills, plastic laser cutting machines are where it’s at. Trust me, once you get a taste of that laser-cut precision, you’ll never wanna go back to the old-school ways again! 🙌

- Benefits of Plastic Laser Cutting Machines:

Aight, fam, let’s talk about why plastic laser cutting machines are the absolute bomb dot com! 💣💥

First up, speed – these machines are like the Flash on steroids! Ain’t nobody got time to sit around waiting for hours on end for their cuts to finish. With plastic laser cutting machines, you can get your projects done in record time, leaving you with more time to do the stuff you actually wanna do. Plus, the accuracy is next-level – we’re talking precision cuts so clean, you’d think a robot did it (spoiler alert: it kinda did). Say goodbye to wonky edges and hello to flawless craftsmanship!

Bottom line? Plastic laser cutting machines ain’t just tools – they’re game-changers, revolutionizing the way we create, design, and innovate. So whether you’re a pro maker or just starting out on your crafting journey, trust me when I say this: ain’t no project too big, too small, or too crazy for a plastic laser cutting machine to handle. So go ahead, unleash your creativity and let these machines take your craft game to new heights! 🚀

| Benefits | Description |

| Speed | Cuts through materials in record time, saving hours compared to traditional cutting methods. |

| Accuracy | Delivers precision cuts with clean edges, ensuring flawless craftsmanship every time. |

| Flexibility | Versatile enough to handle a wide range of materials and designs, from simple to intricate. |

| Industry Revolution | Revolutionizes industries like fashion, automotive, and manufacturing with faster production times. |

| Hobbyist Empowerment | Empowers DIY enthusiasts to bring their creative visions to life with professional-quality results. |

With these benefits, it’s clear that plastic laser cutting machines are a must-have tool for anyone looking to level up their crafting game! 🛠️🔥

- Choosing the Right Plastic Laser Cutting Machine.

Alright, fam, it’s decision time – choosing the right plastic laser cutting machine to suit your needs! 🤔💡

Here’s the lowdown: when it comes to picking the perfect machine, you gotta think about what you’re gonna be using it for and how often you’ll be throwing down those sick cuts. So grab your notepad, ’cause I’m about to drop some knowledge bombs on ya!

Factors to Consider When Choosing a Plastic Laser Cutting Machine:

- Power:

- Opt for higher wattage for cutting thicker materials or handling high-volume projects.

- Consider your cutting needs and choose a machine with sufficient power to meet them.

- Size:

- Evaluate the cutting area of the machine to ensure it accommodates the size of your projects.

- Factor in space constraints in your workshop or workspace when selecting the machine size.

- Additional Features:

- Look for features like touchscreen interfaces for user-friendly operation.

- Consider auto-focus systems or advanced cutting controls to streamline your workflow and enhance precision.

First up, let’s talk power – and no, I ain’t talking about flexing those muscles (although that’s important too). When it comes to plastic laser cutting machines, power is key. The higher the wattage, the more juice your machine’s got to blast through those materials like a boss. So if you’re planning on cutting thicker plastics or cranking out projects like it’s nobody’s business, you’ll wanna go for a machine with some serious power behind it.

And let’s not forget about those sweet, sweet additional features. From fancy touchscreen interfaces to auto-focus systems that make your life a breeze, there’s a whole world of bells and whistles out there to explore. Just remember to keep your budget in mind and only splurge on the features that’ll really level up your crafting game.

So there you have it, fam – power, size, and features are the name of the game when it comes to choosing the right plastic laser cutting machine for you. Do your homework, weigh your options, and before you know it, you’ll be the proud owner of a machine that’s as badass as you are! 💪✨

Key Features to Look Out For:

- Wattage:

- Higher wattage means more cutting power, ideal for thicker materials or frequent use.

- Cutting Area:

- Ensure the machine’s cutting area is large enough to accommodate your project sizes without restrictions.

- User-Friendly Features:

- Touchscreen interfaces and intuitive controls make operation easier and more efficient.

- Advanced Functionality:

- Auto-focus systems and precise cutting controls enhance accuracy and streamline workflow.

Getting Started with Plastic Laser Cutting.

Alright, fam, buckle up ’cause we’re diving into the world of plastic laser cutting! 💥 Here’s your ultimate guide to getting started like a pro. First things first, safety is non-negotiable. Before you even think about firing up that laser, make sure you’re geared up with safety goggles and any other necessary protective gear. Safety first, always!

Next, get your materials prepped and ready to roll. Make sure they’re flat, clean, and free from any debris that could mess with your cuts. Power up your plastic laser cutting machine and make sure everything’s in tip-top shape. Check the alignment of the laser beam and adjust as needed for optimal cutting precision.

Key Steps for Getting Started with Plastic Laser Cutting:

- Prioritize Safety: Gear up with safety goggles and protective gear before starting. Ensure your workspace is clear of any hazards.

- Prepare Materials: Flatten and clean your materials to ensure smooth cutting. Check for any debris that could affect the cutting process.

- Set Up the Machine: Power up the laser cutting machine and check the alignment of the laser beam. Make any necessary adjustments for optimal cutting precision.

- Load and Adjust Designs: Load your design files into the machine’s software and adjust their size or position as needed. Fine-tune cutting settings for the specific material being used.

- Start Cutting: Press the start button and let the machine do its work. Monitor the cutting process and make any adjustments if necessary.

Now, load up your design file into the machine’s software. Make any necessary adjustments to the size or position of your design before sending it to the cutter. Fine-tune your cutting settings based on the type and thickness of your material. You want to find that sweet spot where you get clean, precise cuts without scorching or melting your plastic.

Once everything’s good to go, it’s time to press that magic start button and let the machine work its laser-cutting wizardry. Sit back, relax, and watch as your designs come to life before your eyes!

Now, let’s talk maintenance and troubleshooting. Regularly clean the lens and mirrors of your laser cutting machine to ensure optimal performance. Dust and debris can mess with your cuts and reduce cutting quality. Periodically check and adjust the focus of your laser beam to maintain crisp, clean cuts. A properly focused laser is essential for achieving the best results.

Inspirational Projects and Ideas

Before you even think about hittin’ that start button, make sure your materials are on point. Flatten ’em out, clean ’em up, and get rid of any pesky debris that could mess with your cuts. Clean workspace, clean cuts – you feel me? Time to bring that bad boy to life! Power up your plastic laser cutting machine and make sure everything’s in tip-top shape. Check that laser alignment and make any adjustments needed to ensure you’re gonna get those precision cuts we all dream of.

Get those design files loaded up into the machine’s software and let your creativity run wild. Tweak those designs, resize ’em if needed, and get ’em lookin’ just right before you hit that cut button. It’s your time to shine, so own it! Now it’s time to dial in those cutting settings like a pro. Adjust the power, speed, and focus to match the type and thickness of your material. Trust me, findin’ that sweet spot is gonna make all the difference in the world.

Maintenance and Troubleshooting Tips:

- Regular Cleaning: Clean lenses and mirrors regularly to maintain cutting quality and prevent buildup of dust and debris.

- Focus Adjustment: Check and adjust the focus of the laser beam as needed to ensure clean, precise cuts.

- Proactive Maintenance: Keep an eye out for signs of wear or damage on machine components. Replace worn parts promptly to avoid issues during cutting.

- Stay Calm and Troubleshoot: If issues arise during cutting, remain calm and systematically troubleshoot the problem. Double-check settings, material alignment, and machine functionality.

Keep an eye on that laser focus and make adjustments as needed to maintain those crisp, clean cuts. A well-focused laser is key to gettin’ the results you want, so don’t skimp on this step. Don’t wait ’til things go south – keep an eye out for any signs of wear or damage on your machine’s components. Replace any worn parts pronto to avoid any hiccups in your cutting game.

If you hit a snag during cutting, don’t stress! Take a breather, double-check your settings and material alignment, and troubleshoot like the boss you are. You’ve got this! With these tips and tricks up your sleeve, you’re ready to tackle plastic laser cutting like a true pro. So go ahead, unleash your creativity, and let those laser beams work their magic! 🚀🔥

Inspirational Projects and Ideas:

- Custom Wall Art: Create personalized wall decor to add a unique touch to your space.

- Unique Jewelry: Design and craft your own custom jewelry pieces for a one-of-a-kind look.

- Functional Accessories: Make practical items like phone stands and laptop skins that are both stylish and useful.

Conclusion

Alright, fam, it’s time to wrap things up and drop some final gems of wisdom on y’all. So let’s do this!

We’ve covered some serious ground today, from breaking down the basics of plastic laser cutting to unleashing your creativity with epic projects and ideas. We’ve talked safety, we’ve talked technique, and most importantly, we’ve talked about the sheer awesomeness of plastic laser cutting machines.

But here’s the deal – we’ve only scratched the surface. There’s a whole world of possibilities out there just waiting for you to explore. So don’t be afraid to dive in headfirst and see where your creativity takes you. Whether you’re a seasoned pro or just starting out on your crafting journey, there’s something truly magical about bringing your ideas to life with a plastic laser cutting machine.